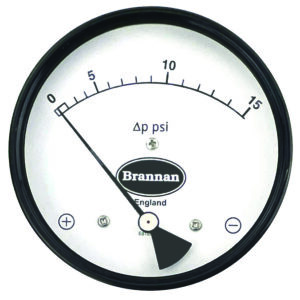

Pressure Gauges

The pressure gauges below are activated by a responsive metal element which deforms under the effect of the pressure being measured. The following British and European Standards form the basis of the design and manufacture of these pressure gauges and of these guidelines. They should also be the source of reference for additional information:

BS EN 837-1 : 1998 – Bourdon Tube Pressure Gauges – Dimensions, Metrology, requirement and testing.

BS EN 837-2 : 1998 – Selection and Installation recommendations for pressure gauges.

BS EN 837-3 : 1998 – Diaphragm and Capsule Pressure Gauges – Dimensions, Metrology, requirement and testing.

Showing all 5 results

Pressure Gauge Selection

Pressure Range – The range of the pressure gauge should be selected such that the maximum working pressure does not exceed 75% of the full scale value, when measuring constant pressure, or 65% for fluctuating pressure.

Safety Design – The criteria for selection of the safety design required for any gauge is a function of four factors. The pressure range (up to 25 bar or over 25 bar); the dial size (less than 100mm or 100mm and above); whether the gauge is ‘dry’ or liquid (eg glycerine) filled; and the state of the material under pressure (as a liquid or as gas or steam). ‘Dry’ gauges with dial diameter 100mm and above are fitted with a blow out device, safety design code S1. All these gauges are suitable for use with liquids to any pressure range. They are also suitable for use with gas or steam up to 25 bar. Above 25 bar, a safety pattern gauge is required for gas or steam pressures. Certain gases, oxygen and acetylene, require special gauges which should be marked accordingly. They must be used with safety pattern gauges and oxygen gauges must be degreased and free of oil. Oxygen and strong oxidising fluids must not be used with glycerine filled gauges.

Materials – Those parts of a pressure gauge which are in contact with the fluid being measured (the ‘wetted parts’) are, as standard, made from alloys or copper (brass and phosphor bronze) but can be stainless steel or other more exotic materials. If a customer is in doubt as to the suitability of the standard gauge, the supplier should be consulted. Standard gauges should not be used in conjunction with fluids which could solidify or where the process materials could deteriorate or be contaminated within the gauge (eg, foodstuff, dairy products). Special diaphragm type or hygenic gauges can be supplied for such applications.

When atmospheric conditions could corrode the case or other non wetted parts, stainless steel cases and movements may be specified.

Storage and Transport

Gauges should be kept in dry, clean conditions within a temperature range of -40 to +60°C and should be protected from impact damage.

Installation

General – When installing a gauge the user should check that the correct range and type has been selected. It is advisable to install the gauge with an isolation cock or valve which facilitates removal of the gauge for maintenance or replacement. On installation a leak tight seal should be achieved. If using sealing materials, ensure these do not prevent the fluids entering the gauge. When tightening the gauge, a spanner must be used on the flats of the gauge shank. Never use the instrument case as a means of tightening. Gauges should be mounted vertically unless designed (and marked) for another attitude. Gauges fitted with a blow out device must have at least 20mm clearance from any obstacle to permit the blow out device to operate correctly (particular attention to this should be given for gauges which are panel or wall mounted).

Conditions – If a gauge would be subject to mechanical shocks it should be mounted remotely using a flexible pipe. If the location is subject to vibration then a liquid filled gauge should be selected. If there are pressure pulses, the gauge may be protected with a damper device, or such a device could be installed into the gauge at manufacture. Installation should take account of the ambient temperature conditions and should these effect the gauge adversely (eg cause the medium to freeze within the pressure element), then the gauge should be located remotely. A pressure gauge should not be installed in contact with fluids whose temperature is outside -30 to +60°C. Under these conditions a syphon should be installed or a suitably removed location selected where the temperature conditions can be more suitable.