Who invented the Bourdon pressure gauge?

The pressure gauge was invented by a French engineer named Eugene Bourdon (1808-1884). He initially designed the instrument for steam locomotive engines in an effort to reduce the very high accident rate and number of deaths from steam engine explosions. He patented the pressure-measuring device that we refer to today as the Bourdon tube.

In 1852, Edward Ashcroft bought the US Patent of Bourdon’s design and he became a well-known gauge manufacturer. When Bourdon’s patents expired in 1875, Bernard Schaeffer of Magdeburg, Germany, began to manufacture gauges via his own company, Schaeffer and Budenburg.

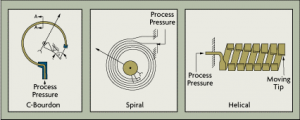

Bourdon tube pressure gauges are one of the most widely used instruments for measuring the pressure of liquids and gases of all kinds, including steam, water and air pressures. They cover measuring ranges from 600 mbar to 4,000 bar. The measuring element is a curved tube with a circular, spiral or coiled shape, commonly called a Bourdon tube. This tube moves outward when the pressure inside the tube is higher than the external pressure, and inward when the internal pressure is lower. This motion is proportional to the pressure to be measured, and it is coupled to the pointer mechanism.

C-type Bourdon tube

C-type Bourdon tubes are fabricated by flattening the side of a hollow tube, then bending the tube into the shape of a “C.” One end of the tube is sealed, and the other end is fixed to a support base. The material of the tube is selected for its elastic properties because it can deform under pressure then return to its original shape when pressure is removed. The actual amount of tip displacement is relatively small, about 6mm. The small and nonlinear tip-motion characteristics are compensated for mechanically which is coupled to the pointer mechanism.

Spiral-type Bourdon tube

One limitation of the C-type bourdon tube is the relatively small amount of tip movement. A spiral-type bourdon tube provides more tip movement.

The spiral-type tube works under the same observed principles as the C-type, but as the applied pressure increases, the spiral uncoils. Because of the increased tip movement, mechanical amplification is not normally needed. This results in an increase in sensitivity and accuracy because there is no lost motion from loose or sticking links, levers, or gears.

Helical-type Bourdon tube

A helical-type bourdon tube provides even greater tip movement than the spiral-type. High-pressure helical-types might have as many as twenty coils, while low-pressure helical-types might have two or three coils. Since the change in tip motion decreases as the applied pressure becomes larger, adding more coils compensates for this motion decrease.

What is the importance of working pressure?

The working pressure is the operating range of a pressure gauge. It is the amount of force being applied to the internal bourdon of the gauge under normal operating conditions. Before installing a gauge, it is vital to know the systems working pressure for safety reasons. Typically, pressure gauges should only be used within 75% of the overall gauge range, however this is reduced with pulsating pressure down to 65%.

For example, if an operating system working pressure is 10 bar, a pressure gauge with the maximum range of 10 bar should not be used. The operating system would overpressure the gauge and the gauge could become damaged. The ideal pressure gauge to use on this operating system would be a gauge with a range of 16 bar, as 75% of this range is 12 bar.

What is EN 837?

EN 837 is the European National Standard for bourdon tube pressure gauges. This standard was approved by the European Committee for Standardisation, of which the United Kingdom is a member. Due to this you may see EN 837 as BS EN 837 as the European Standard has become a British Standard. At Brannan, all our pressure gauges are made to EN 837. EN 837 determines the gauge size, accuracy it needs to conform to, scale divisions and calibration procedure of the gauge.

Brannan sell a wide range of bourdon type pressure gauges, from simple HVAC instruments commonly found on heating systems, to robust, high accuracy fully stainless steel gauges used in oil and gas/process applications. Gauge construction can either be stainless casing with wetted parts and connections, or fully stainless steel with SS316 bourdon and connection. Both Class 1 and Class 1.6 are supplied, and safety glass and micro adjustable pointers are optional variations. Gauge dials can be supplied either with metric or imperial dominant measuring systems.

Brannan are the number one supplier of HVAC pressure gauges in the UK market, and have supplied numerous construction new builds and refurbishments through our network of distributors. For any enquiries or orders please contact sales@brannan.co.uk